by Ace Laboratories | Apr 15, 2024

Types of Wiper Blade Tests One of the most common wiper blade tests is the initial wipe test, a reliable first assessment of the blade’s performance. A wiper blade is tested on a glass windshield for a desired make and model of vehicle and given a grade on a scale...

by Ace Laboratories | Mar 2, 2023

Experience ACE has extensive experience in tire, automotive, and rubber industry testing to help you ensure that your products meet high-performance demands and compliance requirements. Our technical sales team can help you design a study or a testing protocol to...

by Ace Laboratories | Sep 12, 2022

Test Details There are a number of factors to consider when designing and developing a product that will be subjected to long-term sunlight and outdoor exposure. Ultraviolet (UV) rays, ozone, and solar radiation can all cause different reactions in a given material or...

by Maria Vince | Jul 2, 2019

Test Details DMA collects data pertaining to the loss modulus and the storage modulus of a polymer sample, and from this analysis many characteristics can be observed and measured such as filler effect, glass transition, stress relaxation and cure behavior. DMA is...

by Ace Laboratories | Feb 25, 2019

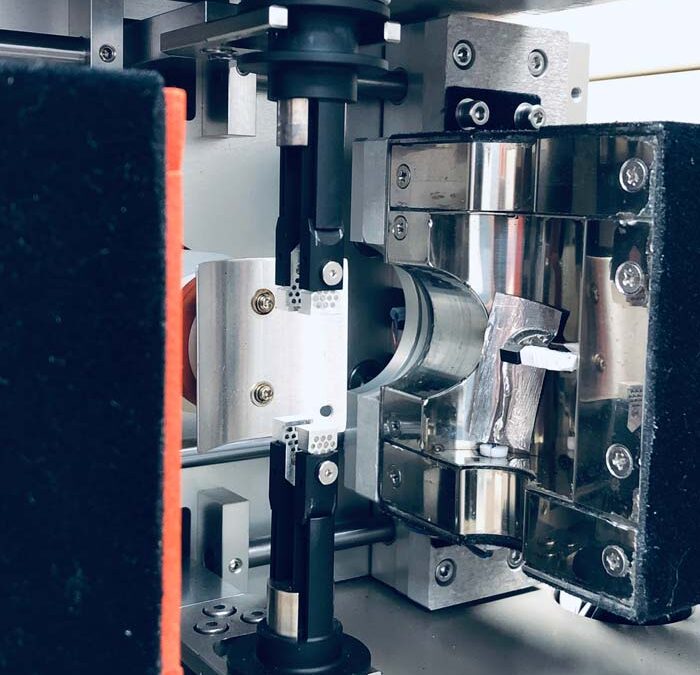

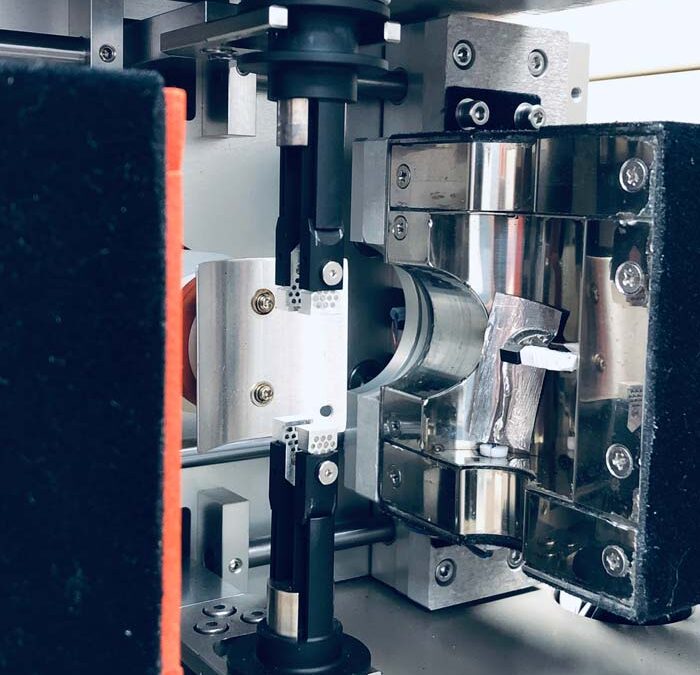

Test Details ASTM D430 measures the dynamic fatigue on materials through cyclic flexing through surface cracking and break. ASTM D813 provides an estimation of a materials ability to resist crack growth through cyclic flexing of a pierced test specimen. ASTM D4482...