by Ace Laboratories | Feb 25, 2019

by Ace Laboratories | Feb 25, 2019

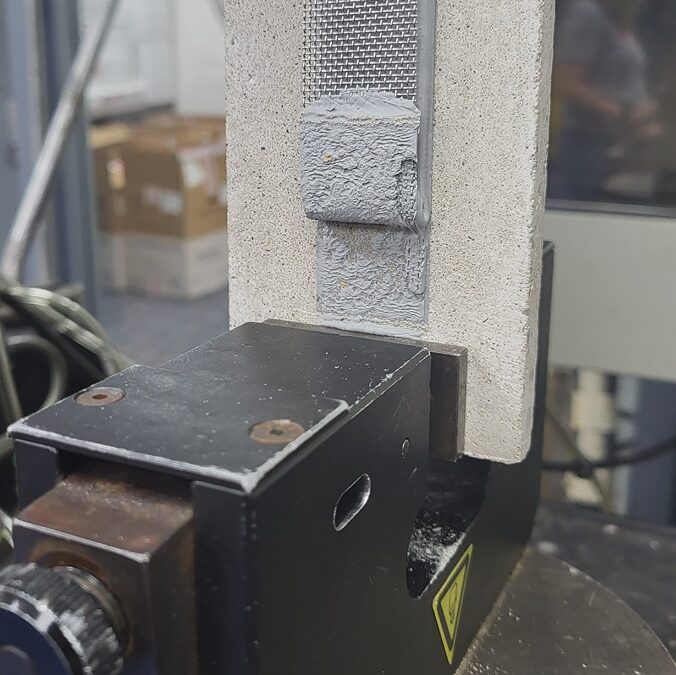

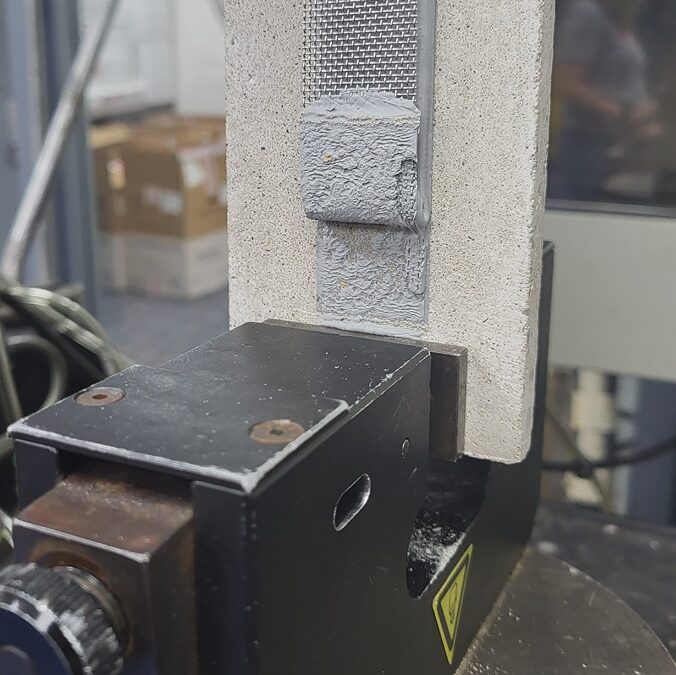

Because tensile testing reveals so much about final product performance, it has an incredibly wide range of applications across industries and product types. The automotive, aerospace, medical, and construction industries utilize tensile testing to optimize material...

by Ace Laboratories | Feb 25, 2019

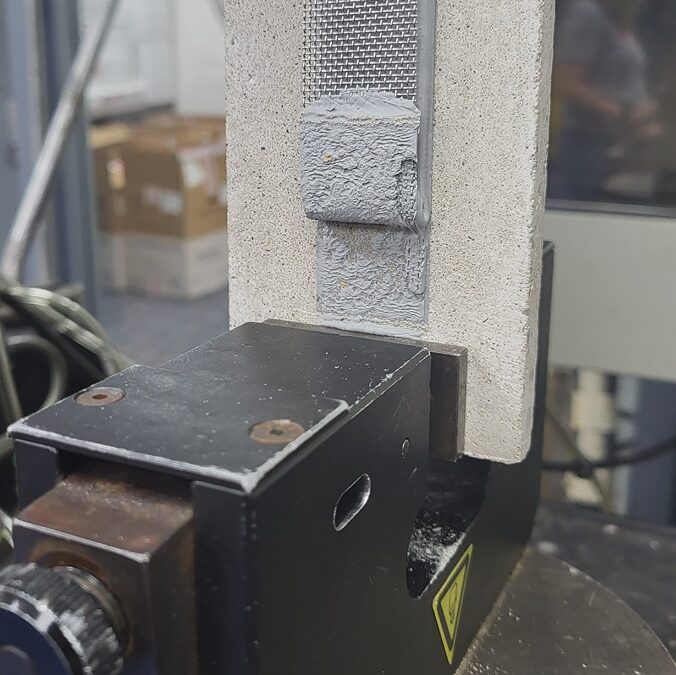

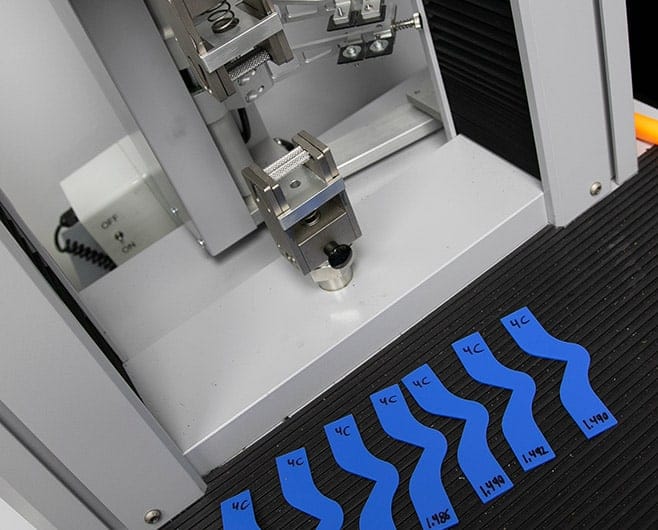

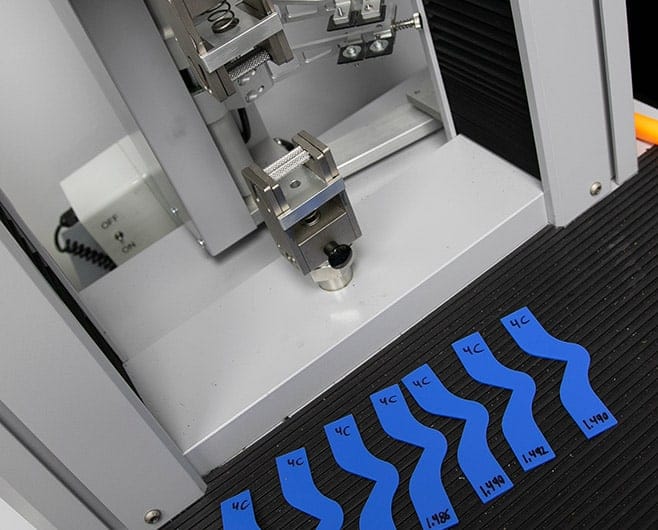

Test Details This test method is used to evaluate the tear strength of common vulcanized rubbers and thermoplastic elastomers. Tear strength can be influenced by mechanical fibering (surface cracking), stress distribution, strain rate, and size/dimensions of the test...

by Ace Laboratories | Feb 25, 2019

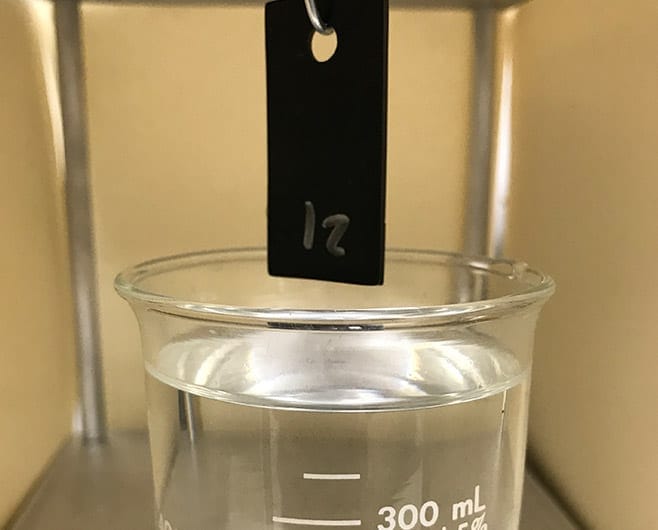

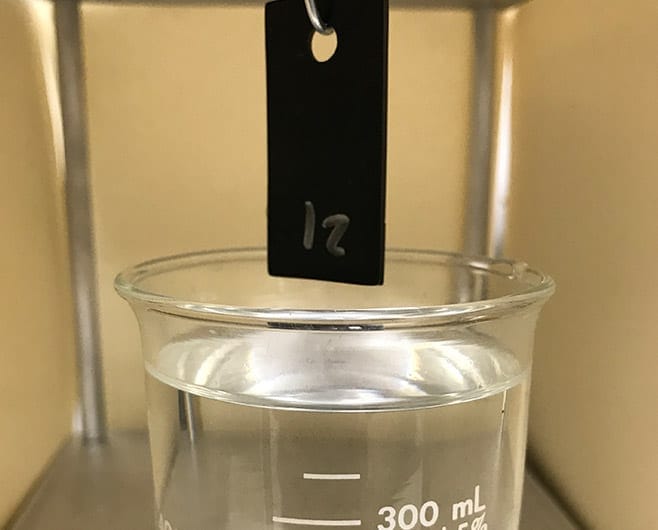

Due to differences in composition, porosity, crystallinity, and thermal history, there may be slight variations in density throughout a larger sample or product. Specific gravity testing data is often used to calculate the average density of the larger product....

by Ace Laboratories | Feb 25, 2019

Test Details ASTM D3182 sets standards for the weighing of materials, the mix process, and preparation of standard vulcanized slabs. ASTM D3183 goes on to identify the practice for preparing samples for testing and the initial conditioning requirements prior to...