Analytical Testing Processes

ACE LaboratoriesAt ACE Laboratories, we pride ourselves on our state-of-the-art analytical testing process and technologies. ACE’s analytical laboratory testing provides the data necessary to ensure quality control, support research and development, and inspire innovation and problem-solving across industries.

What is Analytical Research?

Analytical testing is a type of research involving critical thinking and fact evaluation. There is more than one way to conduct analytical research. You could find an analytical research paper on any topic, like literary research, public opinion, meta-analysis, and scientific trials.

Analytical research can be conducted across fields, from economics to history to science. At ACE, our analytical research focuses on the performance of your material, always with the end-user, end application, and industry standards and requirements in mind.

Consult with ACE to determine which types of research are right for your company.

What is Analytical Testing?

Analytical testing, or materials testing, describes a wide range of analytical techniques used to examine the chemical makeup and chemical characteristics of a given sample.

Analytical testing at its simplest is considered descriptive research, which focuses on the “what” of your material—what is it made of, how does it perform—rather than the why.

At ACE, we work with you to design a series of testing services to predict your material’s performance and to gauge its qualities. This plan may involve physical testing, analytical testing, or both, depending on your goals, industry, and material.

Physical testing focuses on the physical strengths and qualities of your raw materials. Analytical testing, however, is more concerned with the chemical makeup and characteristics of your sample.

Analytical Testing Methods

Your analytical testing at ACE will be made up of multiple types of testing methods. We are experts in designing custom testing plans to fit your exact needs. Below, you will find descriptions of some of our more popular analytical testing methods.

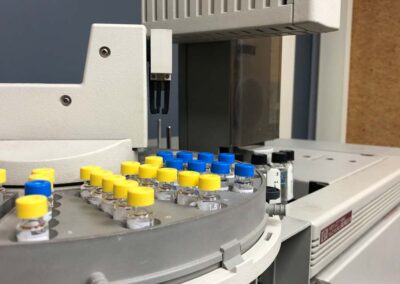

Liquid Chromatography

We use liquid chromatography, or High-Performance Liquid Chromatography (HPLC) when we want to detect a wide range of analytes in a solution, either qualitatively or quantitatively.

To do so, carrier gas and a mobile phase separates analytes of different sizes using a stationary phase column.

So who needs to test their material with HPLC? We recommend this testing method for anyone who needs to determine the purity content of their raw materials, like accelerators and silanes.

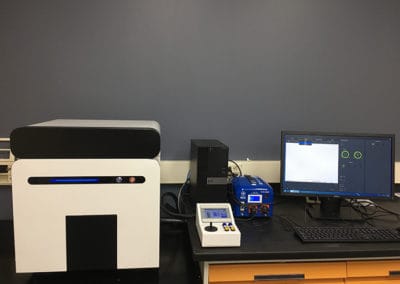

Electron Microscopy

We use our Scanning Electron Microscope (SEM) to perform electron microscopy.

The SEM produces an incredibly high-resolution image. This allows us to observe the sample with emphasis on depth and structure, which lacks in standard optical microscopes.

This cutting-edge technology allows us to analyze materials qualitatively, quantitatively, and by thickness.

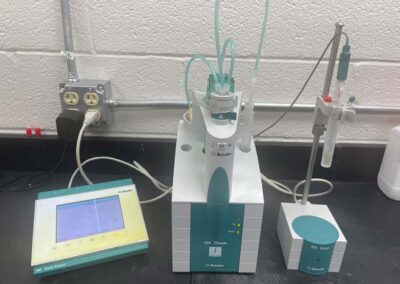

Thermogravimetric Analysis (TGA)

Thermogravimetric Analysis (TGA) is used for a broad variety of purposes. From quality control to material screening, our research-grade TGA equipment delivers consistent, quick results. Understanding the composition of your material is an important foundation for quality-related problem-solving.

TGA is especially useful when you want to compare your sample to a known material through compositional analysis.

When using the TGA, we employ a thermogravimetric technique to analyze the composition of your material. We identify organics, like oils and polymers, and carbon black and ash in your rubber compound.

Amounts of certain components, like plasticizer or oil, can be determined separately by using Test Method D297.

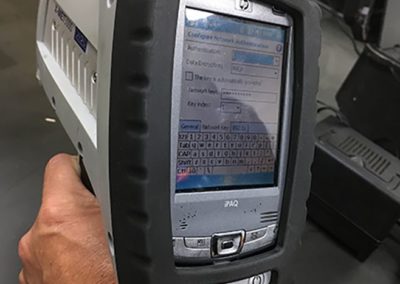

X-Ray Fluorescence Analyzer

ACE’s X-Ray Fluorescence Analyzer (XRF) screens your sample or product for a variety of elemental compositions. These compositions include heavy metal, which is of great interest to manufacturers looking to meet heavy metal compliance standards.

The XRF is non-destructive, and can, therefore, be used on finished goods as well as samples. This testing tool is the most common tool used for those seeking RoHS compliance. It also helps manufacturers meet Prop 65 and lead paint requirements.

Our Analytic Process

At ACE Laboratories, we pride ourselves on our use of analytic processing to get your problems solved, fast.

Whether you are trying to meet an industry code requirement or trying to innovate your product to the next level, ACE is ready to get on board and help you make it happen.

We begin with research questions based on your goals. Then, we design testing—analytical, physical, or both—that will bring us closer to your solution.

When you test with ACE, expect to hear back from us quickly and as often as you want. We’re here to make sure your business runs smoothly.

Material Testing with ACE

ACE wants to see your product reach its highest potential, and we have the tools to help get you there. Our innovative technology and analytical testing methodologies take your excellent product to the next level.

Contact us today to find out how analytical testing can ensure your material’s quality and user-readiness.

Analytical Testing

Learn more about the specific types of analytical testing ACE provides.

ACE analytical laboratory testing services provide:

The Shortest Lead Times

Experience industry-leading turnaround times!

Guaranteed Order Traceability

Repeatability

Our experienced staff performs tests using industry standard processes to guarantee consistent test results.

Compliance

ACE has the capabilities to test to various compliance standards such as RoHS and Cal Prop 65.

ANAB Accredited

As an ISO/IEC 17025 Accredited Laboratory, ACE has been audited to the highest technical competence, traceability, and customer confidentiality standards.

Differential Scanning Calorimetry (DSC)

Differential scanning calorimetry, or DSC, is a thermoanalytical technique. It is used in determining the difference in the amount of heat required to increase the temperature of a sample. The reference is measured as a function of temperature.

FTIR

The Fourier Transform Infrared (FTIR) is commonly used to determine the polymer type present in a compound.

ICP-OES

The ICP-OES California Proposition 65 provides routine ultratrace level analysis to perform analyses at the parts per trillion level and lower.

Scanning Electron Microscope (SEM)

The SEM-MMT X-Factor 150 Scanning Electron Microscope allows qualitative, quantatative, and thickness analysis on materials. The high-resolution imaging of samples provides sample observation with a greater focus on a sample’s depth and structure.

Thermal Conductivity

There are a number of test methods for measuring thermal conductivity of a material, including solids, liquids, powers, and pastes.

Thermogravimetric Analysis (TGA)

This test method is intended for use in quality control, material screening, and related problem-solving. It is useful when a compositional analysis, or comparison to a known material, is desired.

X-Ray Fluorescene (XRF)

The XRF (X-Ray Fluorescence) analyzer is the most common tool used for RoHS compliance testing.

What's Your Challenge?

Tell us about the analytical testing you require. Learn more about our proven, consistent testing methods.