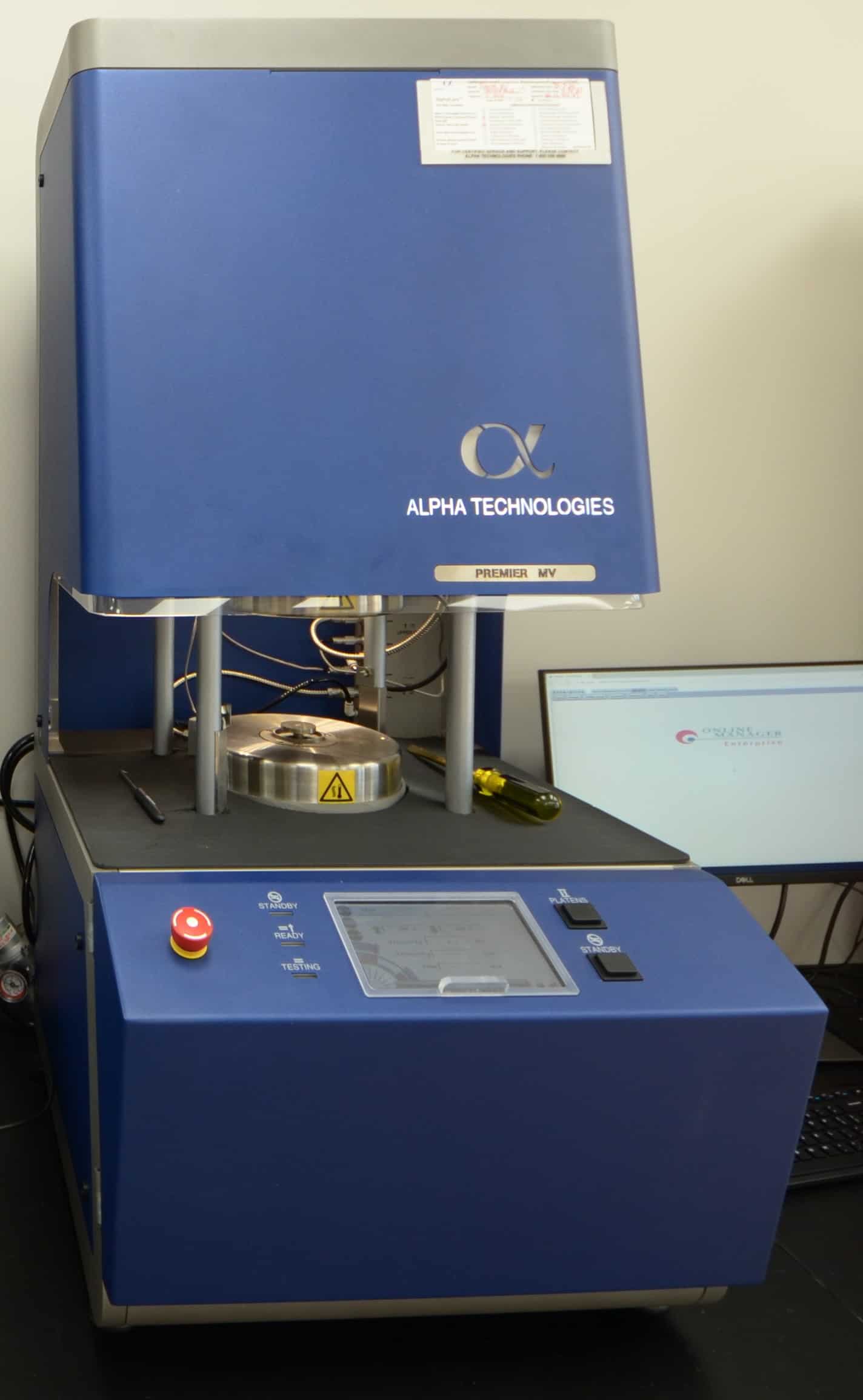

What is a Mooney Viscometer and how is it used? Using a Mooney Viscometer is the primary way rubber testing laboratories test the viscous flow of raw materials, including polymers and intermediates like masterbatches for maintaining stable and consistent manufacturing processes.

Why Use a Mooney Viscometer?

The Mooney Viscometer allows us to perform a variety of tests, including Mooney Viscosity, Mooney Stress Relaxation and Mooney Scorch testing. These three test methods are important because they allow you to understand the viscometer, elastic behavior and scorch time. ACE will provide you with detailed data and analysis to inform your processing plans.

Mooney Viscosity

This test is the most commonly used test method for characterizing uncured rubber materials and polymers. The sample material is heated for a predetermined period of time, then sheared by an embedded rotor at a constant rate.

We then record the Mooney Viscosity and automatically calculate data at defined times and viscosity points. With state-of-the-art equipment and highly trained, experienced laboratory technicians, this test method makes it simple to differentiate between different grades and types of polymers. This allows you to move forward with a high processing consistency.

Elasticity: Mooney Stress Relaxation

Unlike Mooney Viscosity testing, which only provides insight into the flow, or viscosity, of rubber and polymers, Mooney Stress Relaxation testing can assess elastic material behavior.

If you’re interested in understanding your material’s elastic behavior in addition to its viscosity, the two tests can be performed in tandem on the same sample. To add on a Mooney Stress Relaxation test, your technician will observe and record the torque decay after the rotor stops for the viscosity test. They will then calculate the slope-intercept and regression coefficient, providing you with important correlations between polymer branching and processing.

Mooney Scorch

Mooney Scorch testing is incredibly useful to determine the starting of the curing of rubber compounds, also known as the rubber’s scorching behavior. This test provides crucial data to aid in decision-making around production processes as well as a thorough check of your material’s consistency.

What is the Difference between Mooney Viscometer and Rheometer

A viscometer is best for testing viscosity under certain conditions. For example, a viscometer may have a set of fixed speeds to choose from, typically six or more. The Mooney Viscometer provides three types of measurement data, as discussed above: Mooney viscosity, stress relaxation characteristics and scorch time.

The Mooney Viscometer uses high-precision sensors, rotating systems, temperature control systems and advanced data transmission and display methods to provide a wide array of information tailored to your goals.

Rheometers, on the other hand, help us to determine the rheological properties of many materials, including polymer melts and solutions, emulsions, suspensions, inks, coatings and foods. A rheometer provides us with information about the continuous speed scanning process for a complete rheological curve.

A rheometer can provide even more information, such as…

- storage modulus

- loss modulus

- complex modulus

- loss factor

- zero shear viscosity

- dynamic viscosity

- complex viscosity

- shear rate

- shear stress

- strain

- yield stress

- relaxation time

- relaxation modulus

- normal stress difference

- melt extension viscosity

- information on non-Newtonian behavior

- thixotropy

- Rheological cure properties

- expansibility

- pseudoplasticity

As you can see, a rheometer is able to provide a wide range of detailed data points, which can then be used for research and development. Rheometry can be a fast and effective way to learn more about your material, especially when you work with ACE. Our industry-leading turnaround times and thorough lab technicians provide you with quick results that help you optimize your product.

ACE Laboratories

Ready to learn more about the viscosity, elasticity, and scorch time of your rubber sample? Interested in whether the Mooney viscometer or rheometer is better for your unique goals?

Reach out to the experts at ACE Laboratories to get started.