CROSSLINK DENSITY & STATE OF CURE

ACE Laboratories offers practical analytical testing to help you determine if your product has been properly cured to ensure the best product performance. The crosslink density value by itself is not sufficient to determine if a material has been processed and vulcanized correctly. Instead, a more holistic approach is needed to evaluate the state of cure of a material or product. In the ideal case, a sample of uncured material as well as a sample known to be cured to the optimum condition would be used for direct comparison to the samples in question.

Crosslink Density Testing Solutions Offered by ACE Laboratories

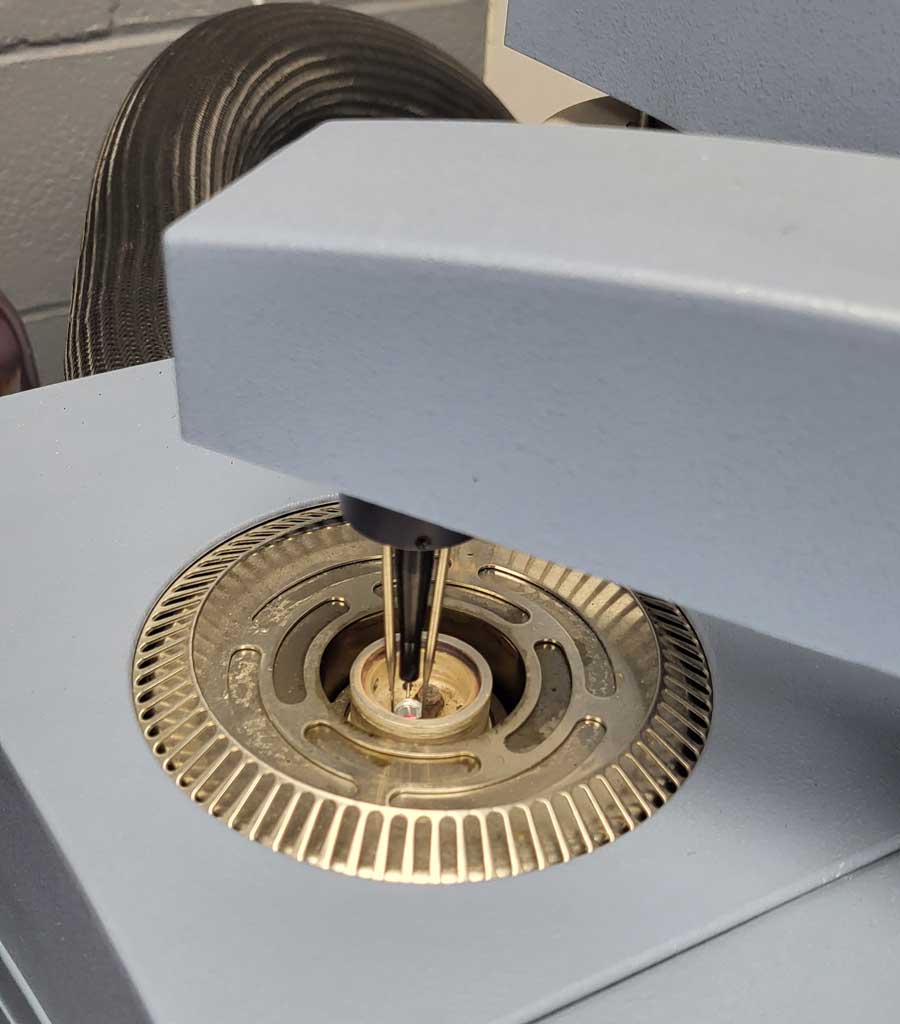

ACE Laboratories uses applied polymer science to offer analytical testing options regarding your polymer-based product’s crosslink density and state of cure. Using solvent swell tests to compare the crosslink density values of different samples is a great technique for quality control to ensure each lot or batch of material has been produced and cured to the same specifications.

In some cases, the crosslink density is not as critical as making sure that the curing reaction has been driven to completion and that the material is not under-cured. This Cure State Analysis by DSC is another strategy we employ in determining if finished products have all been vulcanized correctly. This method can determine if a compound is under-cured, but it cannot tell if a material is over-cured. To perform State of Cure testing, it is best if customers can provide an uncured control sample as well as a control of the known optimum cure state along with the samples in question. The uncured sample is used to determine the total energy needed to fully cure the sample. The known cured sample is used as a benchmark to determine what percentage of the cure is considered optimum for that specific application (it’s not always 100%). The unknown samples are then compared to the uncured and the known cured samples to determine a cure completion percentage of the material in question.

Get Your Crosslink Density Test Done Today!

ACE Laboratories has the solutions if you want to better understand the crosslink density, state of cure, or other properties of your polymer-based products. Reach out today to begin the process of rubber testing with ACE Laboratories.

ACE is an ISO/IEC 17025 Accredited Independent Laboratory

ANAB is an internationally recognized accrediting organization that assures technical expertise and global acceptance of ISO/IEC 17025 accredited laboratories’ test reports for the purposes of free trade and regulatory acceptance.

What is Crosslink Density?

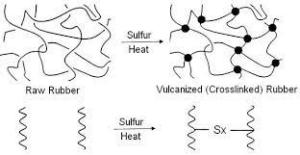

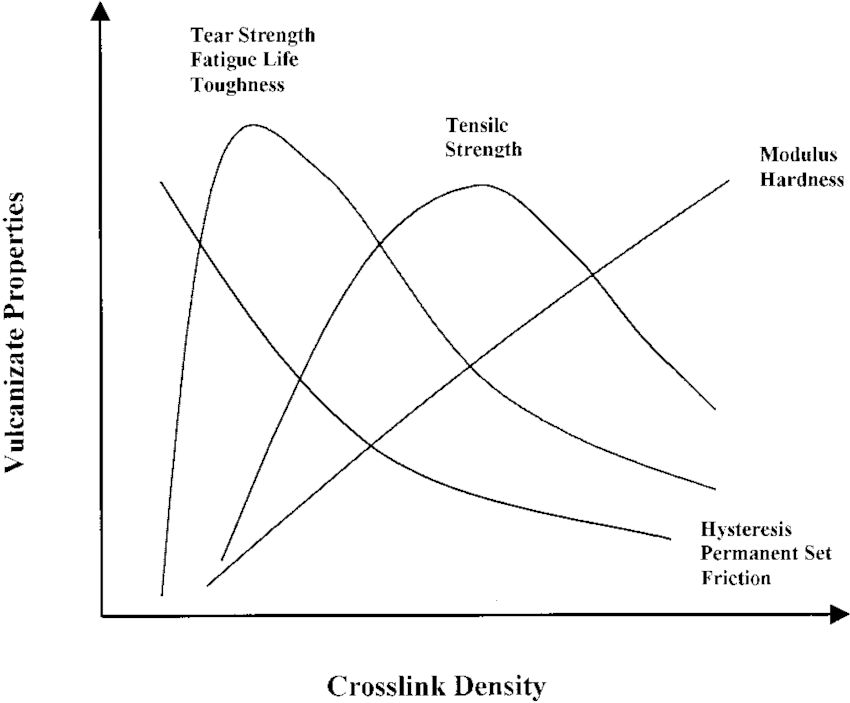

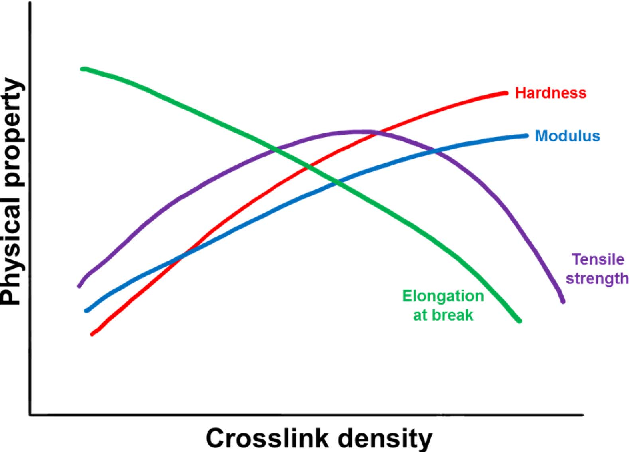

Crosslink density is a measurement of the amount of bonds (typically sulfur-based) between polymer chains in a rubber matrix. Crosslink density can correlate to compound properties such as tensile, elongation, modulus, compression set, and more. If the crosslink density of a particular compound is low, the material will likely have worse compression set properties, lower modulus, and possibly higher elongation. Higher crosslink density will improve compression set as well as tensile strength to a certain point, but eventually, the material loses some of its elongation and flexibility and becomes more brittle.

Crosslink density is often measured by a swell method based on the Flory–Rehner equation. The premise of the method is that more crosslinking in a compound equates to less swelling of the polymer. It’s important to keep in mind that the amount of swelling can also be affected by the molecular weight of the polymer itself, so it’s not a good idea to compare crosslink densities across different grades or types of polymers.

How Does Crosslinking Density Relate to the Tensile Strength of Natural Rubber?

As previously mentioned, the amount of crosslinking will affect the overall stiffness of the rubber compound. If a sample has an exceptionally high crosslink density, it will be comparatively stiff. Contrarily, a lower crosslinking density will result in a more pliable rubber.

Although tensile strength tends to increase as crosslink density increases, there is not a direct correlation between the tensile value and the crosslink density measured by the swell method. In fact, at extremely high levels of crosslink density, some polymers will begin to see a drop in tensile due to the loss in elongation and flexibility. For a scientist, ensuring consistency of both tensile strength and crosslink density can play a vital role in ensuring that your product meets all of the mechanical properties for your application.

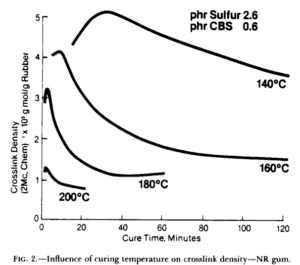

Manipulating Crosslink Density within a Polymer-Based Product Through Curing

The density of crosslinks within a polymer-based compound, is not unchangeable. Manufacturers can manipulate crosslink density based on the vulcanization temperature and duration used in production. During vulcanization, more frequently known as curing, polymer chains and curatives such as sulfur and other accelerators for chemical bonds within the rubber compound. The temperature at which this reaction takes place can affect the total number of crosslinks able to be produced by the same compound (see the figure below for illustration).

Rubber can be cured in various ways using different accelerators or crosslinking agents. These crosslinking agents can produce a wide range in overall crosslink density even within the same polymer system or compound. This allows rubber chemists to adjust a rubber formulation to reach the balance of properties needed for a given application. Whether you are looking for an excellent compression set, maximum elongation, or a combination of tear strength and heat aging, our rubber experts at ACE can help you fine-tune your manufacturing process or modify your material’s cure system to achieve the properties you need for success.

Crosslink Density Testing Solutions Offered by ACE Laboratories

ACE Laboratories uses applied polymer science to offer analytical testing options regarding your polymer-based product’s crosslink density and state of cure. Using solvent swell tests to compare the crosslink density values of different samples is a great technique for quality control to ensure each lot or batch of material has been produced and cured to the same specifications.

In some cases, the crosslink density is not as critical as making sure that the curing reaction has been driven to completion and that the material is not under-cured. This Cure State Analysis by DSC is another strategy we employ in determining if finished products have all been vulcanized correctly. This method can determine if a compound is under-cured, but it cannot tell if a material is over-cured. To perform State of Cure testing, it is best if customers can provide an uncured control sample as well as a control of the known optimum cure state along with the samples in question. The uncured sample is used to determine the total energy needed to fully cure the sample. The known cured sample is used as a benchmark to determine what percentage of the cure is considered optimum for that specific application (it’s not always 100%). The unknown samples are then compared to the uncured and the known cured samples to determine a cure completion percentage of the material in question.

Crosslink Density Testing Solutions Offered by ACE Laboratories

ACE Laboratories uses applied polymer science to offer analytical testing options regarding your polymer-based product’s crosslink density and state of cure. Using solvent swell tests to compare the crosslink density values of different samples is a great technique for quality control to ensure each lot or batch of material has been produced and cured to the same specifications.. I

In some cases, the crosslink density is not as critical as making sure that the curing reaction has been driven to completion and that the material is not under-cured. This Cure State Analysis by DSC is another strategy we employ in determining if finished products have all been vulcanized correctly. This method can determine if a compound is under-cured, but it cannot tell if a material is over-cured. To perform State of Cure testing, it is best if customers can provide an uncured control sample as well as a control of the known optimum cure state along with the samples in question. The uncured sample is used to determine the total energy needed to fully cure the sample. The known cured sample is used as a benchmark to determine what percentage of the cure is considered optimum for that specific application (it’s not always 100%). The unknown samples are then compared to the uncured and the known cured samples to determine a cure completion percentage of the material in question.

Get Your Crosslink Density Test Done Today!

ACE Laboratories has the solutions if you want to better understand the crosslink density, state of cure, or other properties of your polymer-based products. Reach out today to begin the process of rubber testing with ACE Laboratories.

ACE is an ISO/IEC 17025 Accredited Independent Laboratory

ANAB is an internationally recognized accrediting organization that assures technical expertise and global acceptance of ISO/IEC 17025 accredited laboratories’ test reports for the purposes of free trade and regulatory acceptance.